Corrugated Container and Display Manufacturing

Intuitive, reliable, and budget-friendly systems for corrugated container manufacturing, protective packaging, and point-of-purchase (POP) display assembly.

With over 40 years of experience manufacturing hot melt equipment, HMT® has the adhesive dispensing solution for your corrugated products. Our hot melt systems are easily configured with a variety of tank, pump, and motor combinations to meet the specific requirements of your application. Running a high-volume folder-gluer? Try one of HMT’s ProFlex® dual grid systems to maximize melt rate and throughput. Have a lower volume box maker? The AutoPack® 715 may be the cost-effective solution for your container line. Not sure? Contact one of our experts to find the ideal system for your application. Our capabilities include:

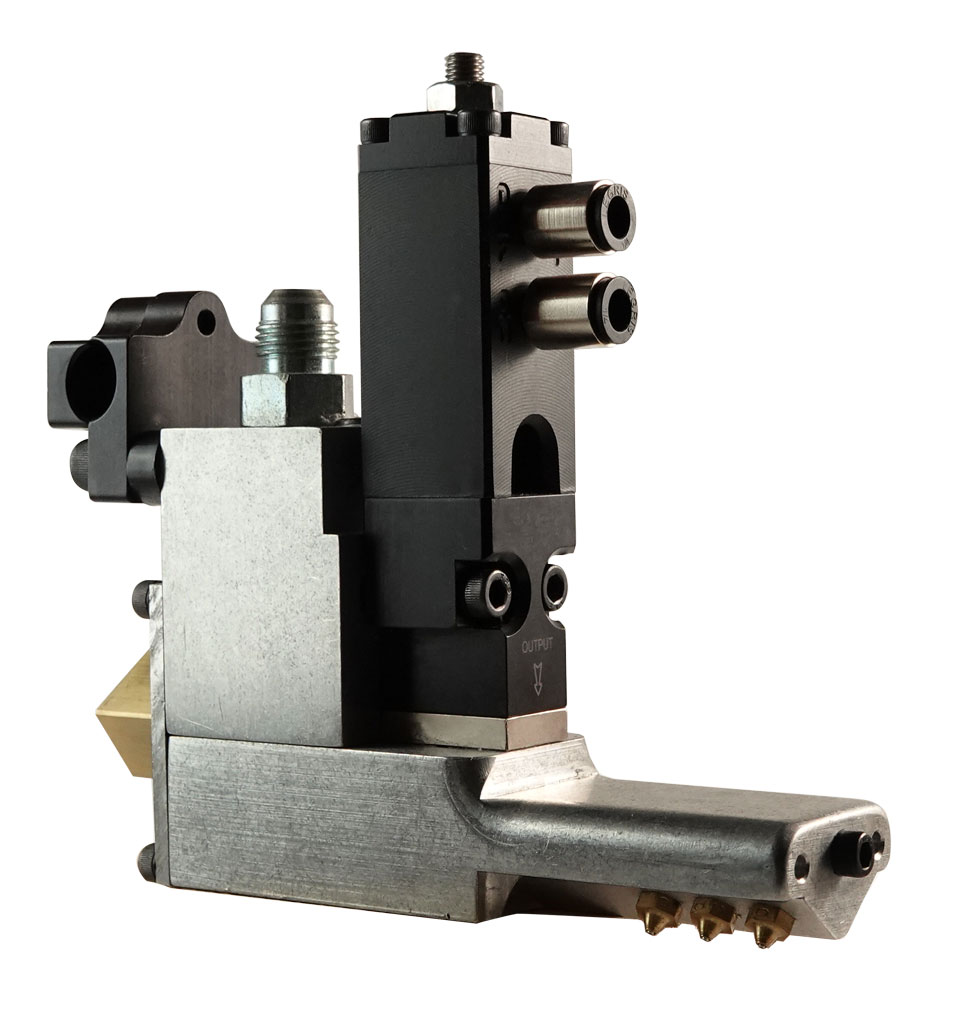

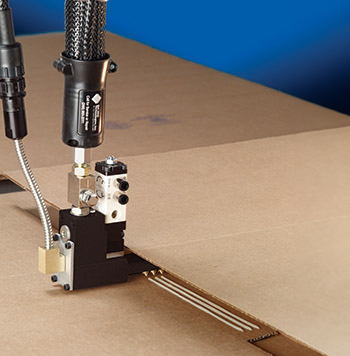

- Customizable multi-bead box making guns for box makers and folder-gluers

- Single or multi-bead automatic glue dispensing heads for in-line protective packaging

- Cost-effective bulk adhesives and industry leading handguns for POP display assembly

If you are using hot glue sticks for your POP display assemblies or end-of-line protective packaging, contact HMT®. We can help you convert to bulk hot melt adhesives and reduce your glue costs substantially. Tired of waiting for your liquid glue to setup or having trouble with hard-to-bond foam dunnage or coated materials? Hot Melt adhesives form stronger bonds faster to foams and coated products than cold glues. Contact HMT® to find the right equipment and adhesive for your corrugated application.

We're a proud member of the AICC

Applications Solutions

Customized for Your Industry

Box Maker

To speed up your box maker and cut costs, look no further than hot melt adhesives. Our EVAs cost less per box than tape or staples and can be applied to the manufacturing joint at higher speeds. Hot melts offer better adhesion to coated boxes than liquid glue and are the go-to for pilferage resistant packaging. Pair one of our adhesives with an AutoPack® 715 hot melt system and our TP Series Box Making Gun to upgrade your box maker today!

- Low to Medium Volume

- Box Making Guns

- Pilferage Resistant Packaging

Recommended Equipment & Glue

Folder-Gluer

Hot Melt Technologies® offers a wide range of glue machines, heated hoses, automatic valves, and nozzles to meet the demands of your folder-gluer line. For high output carton manufacturing, a ProFlex® system with a 50 lb tank will meet the melt rate requirements of most box making applications; our 900 Series automatic valves, available in single or multi-bead nozzle configurations, will provide the ideal glue pattern. If you are struggling to adhere coated containers, try one of our hot melt EVAs. We offer a variety of formulations that will outperform liquid glues.

- High Volume

- Single or Multi-bead Apply

- Strong Bonds to Coated Containers

Recommended Equipment & Glue

Protective Packaging

Shipping can be rough, and no one wants to receive damaged goods… Hot Melt Technologies® offers small and large capacity units with manual or automatic glue dispensing guns to meet your in-line or end-of-line protective packaging needs. If you are tired of waiting for liquid glue to set or having an issue bonding foam to corrugate, try a hot melt adhesive. When adhering dunnage to inner packaging, hot melt adhesives are the go-to for speed and strength.

- Automatic or Manual Gluing

- Single or Multi-bead Apply

- Strong Bond to Foams and Corrugates

Recommended Equipment & Glue

POP Displays

- Industry Leading Handguns

- Low-cost Alternative to Glue Sticks

- Cost-effective Bulk Hot Melt Systems